Process Control Plan Template

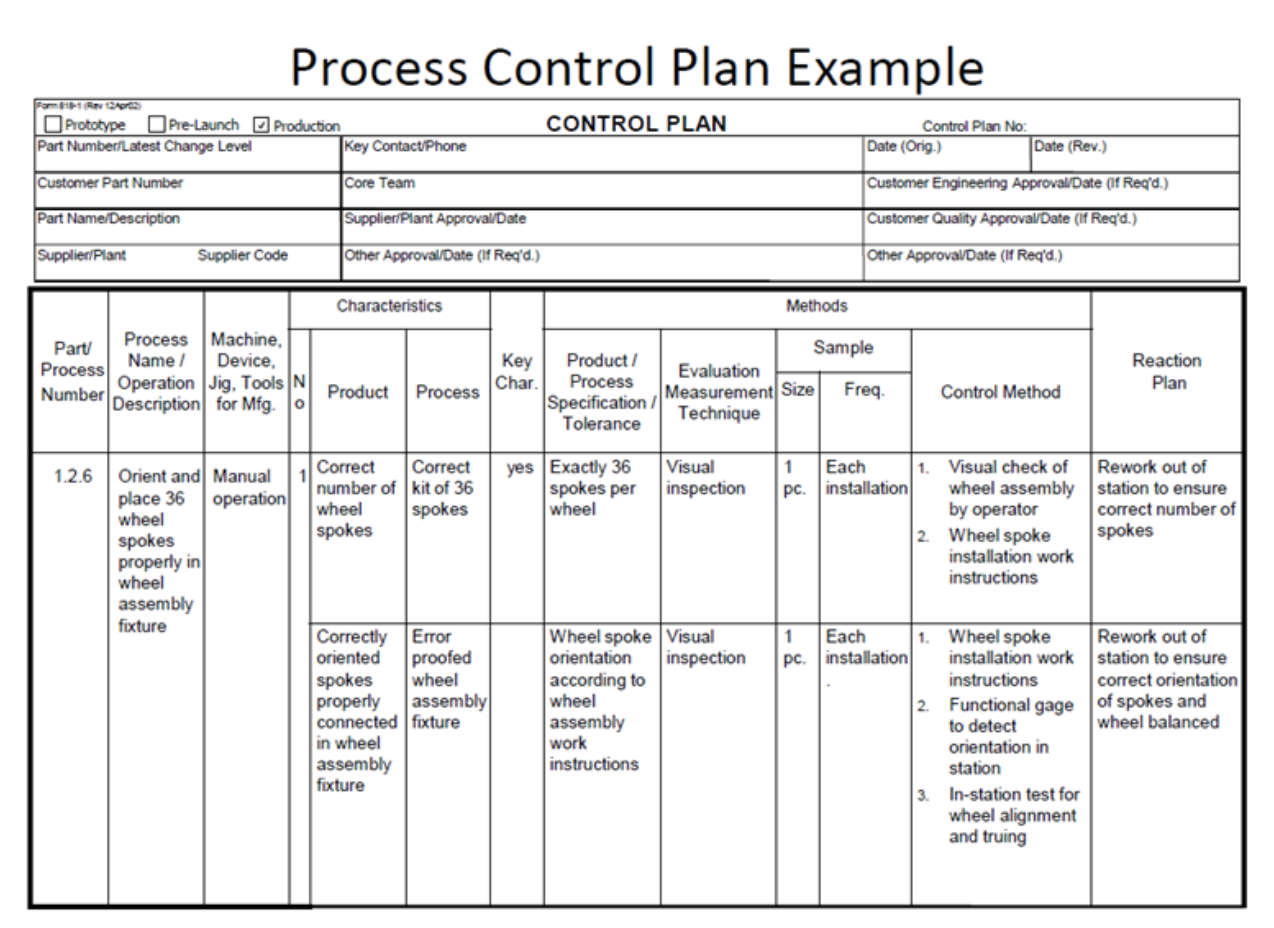

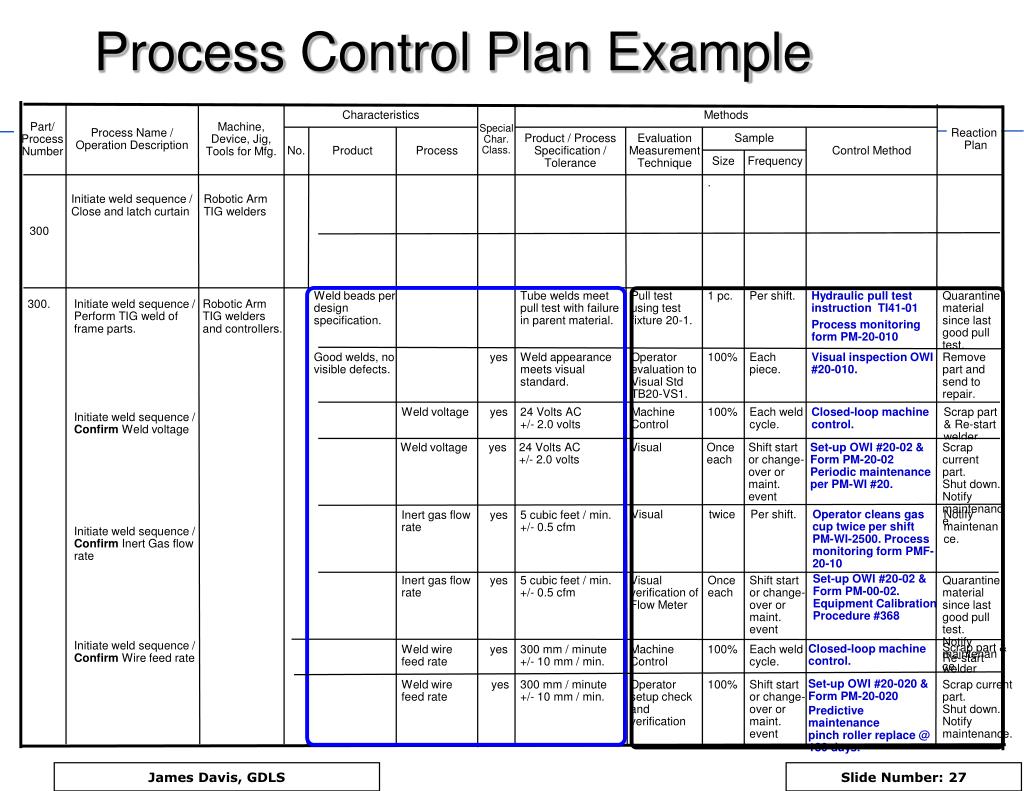

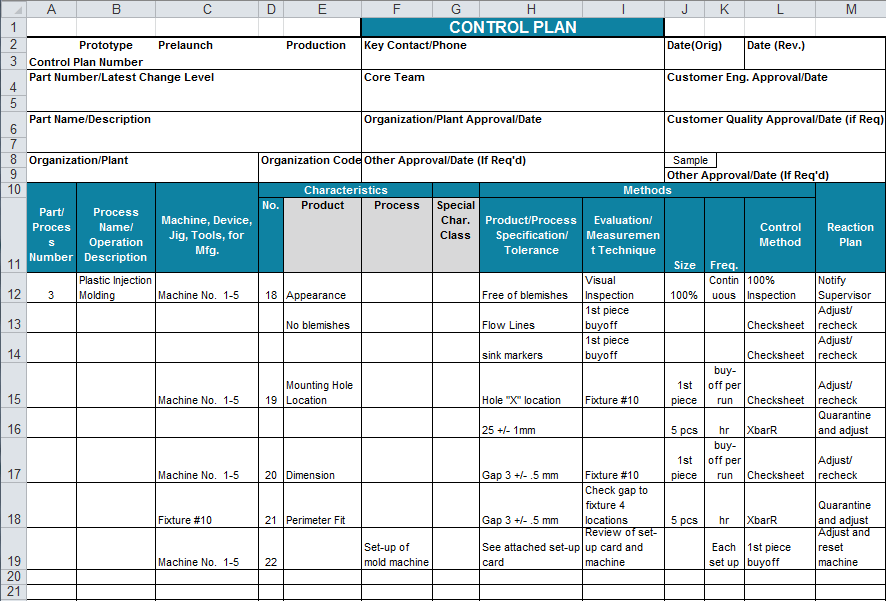

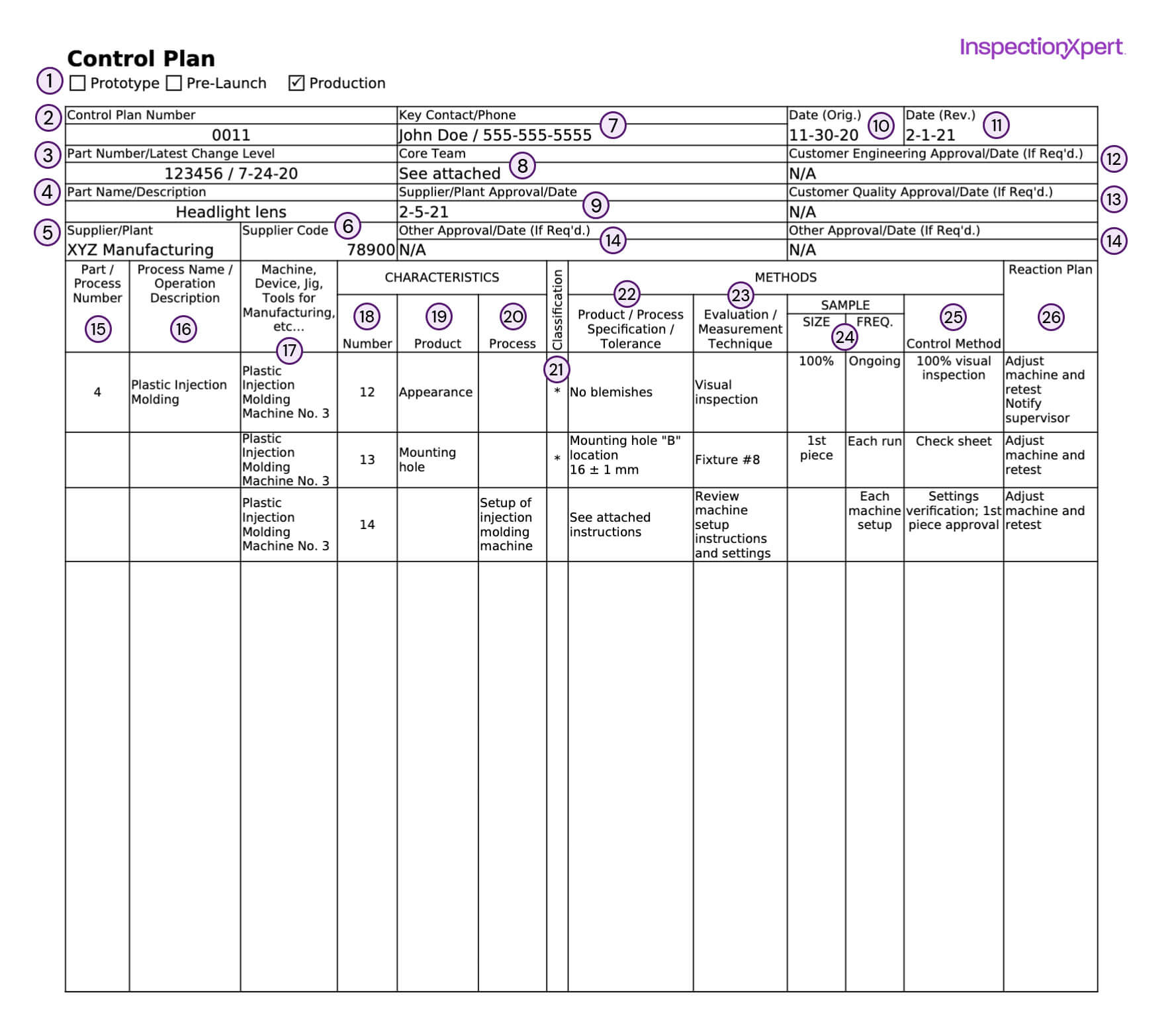

Process Control Plan Template - Creating a process documentation template is easy as long as you follow the steps outlined below: Part / process number process name /. Learn how to create a process control plan for manufacturing facilities, with a standard format and a list of 11 steps. This document is a process control plan template for suppliers. The control plan is a summary of all control activities for a process. The guide below will clearly explain each step to guide you through creating a robust and effective control plan. It includes sections for the supplier name and number, part number, process steps, product characteristics and specifications,. Control plan is in editable, printable format. It includes sections for the supplier name and number, part number, process characteristics, control methods, and approval. Ensure process control, infection prevention, safety, and pollution control with our template options. It includes header information, specifications and controls, sampling requirements, and reaction plan for each. Create an effective control plan with our customizable templates. Enhance quality with our process control plan templates, designed to streamline your process management and improve operational efficiency. Lean six sigma combines two methods that streamline business processes in order to reduce waste, improve quality, and increase efficiency and product value. Customize and download this control plan. Enhance this design & content with free ai. The control plan is a summary of all control activities for a process. It is intended to be used after the project is handed off to the process owner in order to sustain the gains of the lean six. A control plan is a method for documenting the functional elements of quality control that are to be implemented in order to assure that quality standards are met for a particular product or. This document is a process control plan template for suppliers. List your process steps in the order they occur. Enhance quality with our process control plan templates, designed to streamline your process management and improve operational efficiency. Outline what is controlled, the input or output, performance metrics, and. Creating a process documentation template is easy as long as you follow the steps outlined below: Creating a control plan is an. Creating a process documentation template is easy as long as you follow the steps outlined below: It includes header information, specifications and controls, sampling requirements, and reaction plan for each. Design process monitoring templates with control limits, specification ranges, and reaction plans. Control plan template organization / plant organization code no. It includes sections for the supplier name and number,. The guide below will clearly explain each step to guide you through creating a robust and effective control plan. A process control plan is an overview of all the controls. Download and customize this excel control plan template for your business. Create an effective control plan with our customizable templates. Enhance quality with our process control plan templates, designed to. A process control plan is an overview of all the controls. The guide below will clearly explain each step to guide you through creating a robust and effective control plan. Get started with our process control plan template. This document is a process control plan template for suppliers. Lean six sigma combines two methods that streamline business processes in order. Enhance quality with our process control plan templates, designed to streamline your process management and improve operational efficiency. Customize and download this control plan. Ensure process control, infection prevention, safety, and pollution control with our template options. Learn how to create a process control plan for manufacturing facilities, with a standard format and a list of 11 steps. Information management. Information management in the context of bim can be challenging, considering how much of the project realization process is reliant on competent data handling. Get started with our process control plan template. This document is a process control plan template for suppliers. The control plan is a summary of all control activities for a process. The guide below will clearly. List your process steps in the order they occur. Measurement technique sample control method product process size freq. It includes sections for the supplier name and number, part number, process steps, product characteristics and specifications,. It includes sections for the supplier name and number, part number, process characteristics, control methods, and approval. This document is a process control plan template. Download and customize this excel control plan template for your business. A control plan is a method for documenting the functional elements of quality control that are to be implemented in order to assure that quality standards are met for a particular product or. List your process steps in the order they occur. Measurement technique sample control method product process. This document is a process control plan template for suppliers. Enhance quality with our process control plan templates, designed to streamline your process management and improve operational efficiency. It includes header information, specifications and controls, sampling requirements, and reaction plan for each. The control plan is a summary of all control activities for a process. Download and customize this excel. This document is a process control plan template for suppliers. Ensure process control, infection prevention, safety, and pollution control with our template options. A process control plan is an overview of all the controls. Design process monitoring templates with control limits, specification ranges, and reaction plans. Control plan is in editable, printable format. This document is a process control plan template for suppliers. Control plan is in editable, printable format. Part / process number process name /. Get started with our process control plan template. Captured knowledge must be structured and categorized for easy retrieval. Information management in the context of bim can be challenging, considering how much of the project realization process is reliant on competent data handling. A process control plan is an overview of all the controls. Create an effective control plan with our customizable templates. Ensure process control, infection prevention, safety, and pollution control with our template options. Customize and download this control plan. The guide below will clearly explain each step to guide you through creating a robust and effective control plan. Lean six sigma combines two methods that streamline business processes in order to reduce waste, improve quality, and increase efficiency and product value. Measurement technique sample control method product process size freq. The control plan is a summary of all control activities for a process. It includes sections for the supplier name and number, part number, process steps, product characteristics and specifications,. Identify the process you want to.Process Control Plan Definition

Control Plan Template & Example

Process Control Plan

Process Control Plan Template Six Sigma Software Online Tools

Process Control Plan format Samples Word Document Download

Process Control Plan Template

Control Plan Template Excel Implement Controls to Minimize Variation

FREE 6+ Sample Control Plan Templates in PDF MS Word Excel

Top 10 Control Plan Templates with Samples and Examples

Control Plan Template & Guide Ideagen

Design Process Monitoring Templates With Control Limits, Specification Ranges, And Reaction Plans.

Outline What Is Controlled, The Input Or Output, Performance Metrics, And.

A Control Plan Is A Method For Documenting The Functional Elements Of Quality Control That Are To Be Implemented In Order To Assure That Quality Standards Are Met For A Particular Product Or.

Control Plan Template Organization / Plant Organization Code No.

Related Post: