Template Material For Countertops

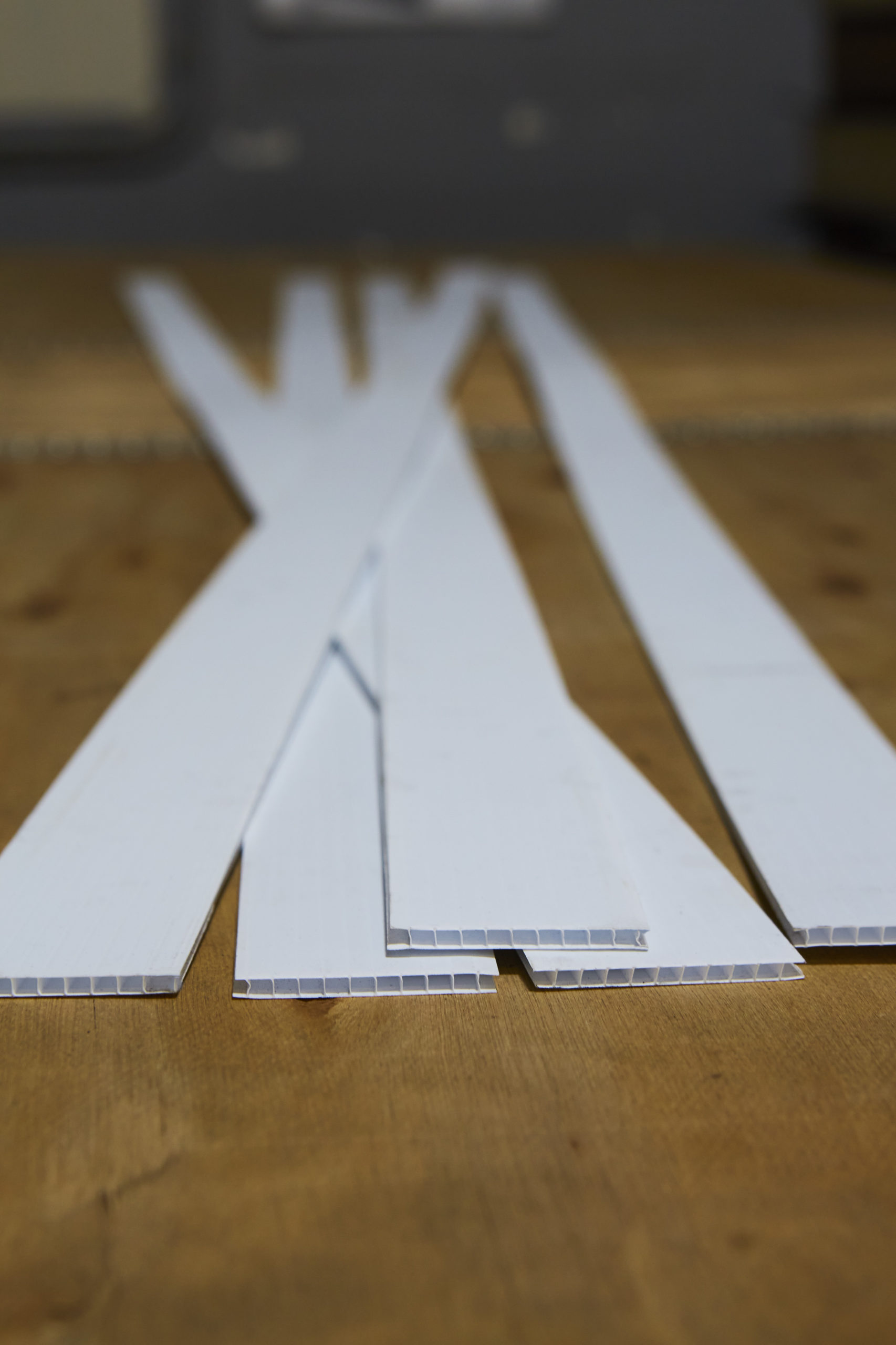

Template Material For Countertops - For the countertop to go together easily, square, and level, it’s important that all the legs beneath it are identical. *hi gabor,i recently made up large (6 diameter) table legs by gluing up 8 oak wedges, each cut at 22.5 degrees. This, in turn, can have a bearing on your choice of material. When i had my granite countertops installed in my kitchen there was this sweet little cutoff about 12 wide left over, i had it sitting in a corner of my shop for about a year before i realized i could spray adhesive a piece of sandpaper on it for flattening the sole of a plane. From the edges of the plywood. This guarantees the template is in the same location when you trace it and then rout the leg flush to it. Assuming you are just duplicating shapes by using a flush trim bit, if you use a thicker material for your template, you can occasionally raise or lower the bit in the router to use a sharper portion of the bit and also transfer the wear on the template edge to a different area. A router bit cuts the material quite nicely, whether for making a straight cut or for decorative edging. Screw the template to the plywood. I'd use a jig saw to cut close to the outline shape and then use my router with a top bearing to clean up the hole. For the countertop to go together easily, square, and level, it’s important that all the legs beneath it are identical. I've not tried carbon paper. This, in turn, can have a bearing on your choice of material. A router bit cuts the material quite nicely, whether for making a straight cut or for decorative edging. It is an acrylic compound (methyl methacrylate) filled with mineral powder for color, body, weight, etc. *hi gabor,i recently made up large (6 diameter) table legs by gluing up 8 oak wedges, each cut at 22.5 degrees. When i had my granite countertops installed in my kitchen there was this sweet little cutoff about 12 wide left over, i had it sitting in a corner of my shop for about a year before i realized i could spray adhesive a piece of sandpaper on it for flattening the sole of a plane. Inset the template 1⁄4 in. Screw the template to the plywood. Core material for countertops rpholland | posted in wood and materials on september 21, 2006 05:31am i am adding a room and remodeling kitchen, and will be making new plastic laminate countertops. When i had my granite countertops installed in my kitchen there was this sweet little cutoff about 12 wide left over, i had it sitting in a corner of my shop for about a year before i realized i could spray adhesive a piece of sandpaper on it for flattening the sole of a plane. Assuming you are just duplicating. When i had my granite countertops installed in my kitchen there was this sweet little cutoff about 12 wide left over, i had it sitting in a corner of my shop for about a year before i realized i could spray adhesive a piece of sandpaper on it for flattening the sole of a plane. *hi gabor,i recently made up. From the edges of the plywood. This, in turn, can have a bearing on your choice of material. When i had my granite countertops installed in my kitchen there was this sweet little cutoff about 12 wide left over, i had it sitting in a corner of my shop for about a year before i realized i could spray adhesive. The impact of each tooth on a saw blade smacking the plastic at high speed tends to fracture the material rather than just slicing it. For the countertop to go together easily, square, and level, it’s important that all the legs beneath it are identical. Epoxy resin makes a great inlay material because it allows you to create delicate, complicated. The impact of each tooth on a saw blade smacking the plastic at high speed tends to fracture the material rather than just slicing it. I'd use a jig saw to cut close to the outline shape and then use my router with a top bearing to clean up the hole. For the countertop to go together easily, square, and. It is an acrylic compound (methyl methacrylate) filled with mineral powder for color, body, weight, etc. This, in turn, can have a bearing on your choice of material. Screw the template to the plywood. For the countertop to go together easily, square, and level, it’s important that all the legs beneath it are identical. *hi gabor,i recently made up large. I'd use a jig saw to cut close to the outline shape and then use my router with a top bearing to clean up the hole. When i had my granite countertops installed in my kitchen there was this sweet little cutoff about 12 wide left over, i had it sitting in a corner of my shop for about a. This, in turn, can have a bearing on your choice of material. I've not tried carbon paper. Screw the template to the plywood. *hi gabor,i recently made up large (6 diameter) table legs by gluing up 8 oak wedges, each cut at 22.5 degrees. I'd make a template from a piece of 1/2 plywood and sand it to the smoothest. Core material for countertops rpholland | posted in wood and materials on september 21, 2006 05:31am i am adding a room and remodeling kitchen, and will be making new plastic laminate countertops. A router bit cuts the material quite nicely, whether for making a straight cut or for decorative edging. For the countertop to go together easily, square, and level,. This, in turn, can have a bearing on your choice of material. Core material for countertops rpholland | posted in wood and materials on september 21, 2006 05:31am i am adding a room and remodeling kitchen, and will be making new plastic laminate countertops. For the countertop to go together easily, square, and level, it’s important that all the legs. This guarantees the template is in the same location when you trace it and then rout the leg flush to it. A router bit cuts the material quite nicely, whether for making a straight cut or for decorative edging. It is an acrylic compound (methyl methacrylate) filled with mineral powder for color, body, weight, etc. When i had my granite countertops installed in my kitchen there was this sweet little cutoff about 12 wide left over, i had it sitting in a corner of my shop for about a year before i realized i could spray adhesive a piece of sandpaper on it for flattening the sole of a plane. Core material for countertops rpholland | posted in wood and materials on september 21, 2006 05:31am i am adding a room and remodeling kitchen, and will be making new plastic laminate countertops. Here, christopher moore explains how to use resin to create stunning inlay and expand your design horizon. It's called a pounce wheel because after the pattern has been perferated (with the pounce wheel), it can be reused with a pounce bag which is chalk powder wrapped in a cloth. For the countertop to go together easily, square, and level, it’s important that all the legs beneath it are identical. From the edges of the plywood. I've not tried carbon paper. I'd use a jig saw to cut close to the outline shape and then use my router with a top bearing to clean up the hole. I'd make a template from a piece of 1/2 plywood and sand it to the smoothest curvature i could. Screw the template to the plywood. *hi gabor,i recently made up large (6 diameter) table legs by gluing up 8 oak wedges, each cut at 22.5 degrees. The impact of each tooth on a saw blade smacking the plastic at high speed tends to fracture the material rather than just slicing it.Corrugated Plastic Template Strips Commercial Plastics Depot

Template Material For Countertops Countertop Templating Material

How to make a Countertop Template Sawdust Girl®

Countertop Template Strips Commercial Plastics Depot

Choose the Right Template Material for Your Countertop A Guide for

Template Material (20 Strips) Create Custom Templates for Counters

How To Make A Countertop Template YouTube

Buy Template Material (20 Strips) Create Custom Templates for

How To Make a Countertop Template Countertops, Templates, How to make

Countertop Template Strips Commercial Plastics Depot

Epoxy Resin Makes A Great Inlay Material Because It Allows You To Create Delicate, Complicated Patterns Without Having To Cut And Match Delicate, Complicated Inlay Pieces.

Inset The Template 1⁄4 In.

This, In Turn, Can Have A Bearing On Your Choice Of Material.

Assuming You Are Just Duplicating Shapes By Using A Flush Trim Bit, If You Use A Thicker Material For Your Template, You Can Occasionally Raise Or Lower The Bit In The Router To Use A Sharper Portion Of The Bit And Also Transfer The Wear On The Template Edge To A Different Area.

Related Post: